The most lightweight bus body

Stainless steel lightweight solutions for the transportation industry

Stalatube is the global leader in stainless steel for bus and coach body tubes, sheets, and components. We supply tailor-made solutions for bus and coach body and chassis structures, providing everything from standard-length tubes to optimized laser-cut and bent components. By choosing the right stainless steel grade and optimizing the structures and dimensions, our customers can significantly decrease their bus body weight.

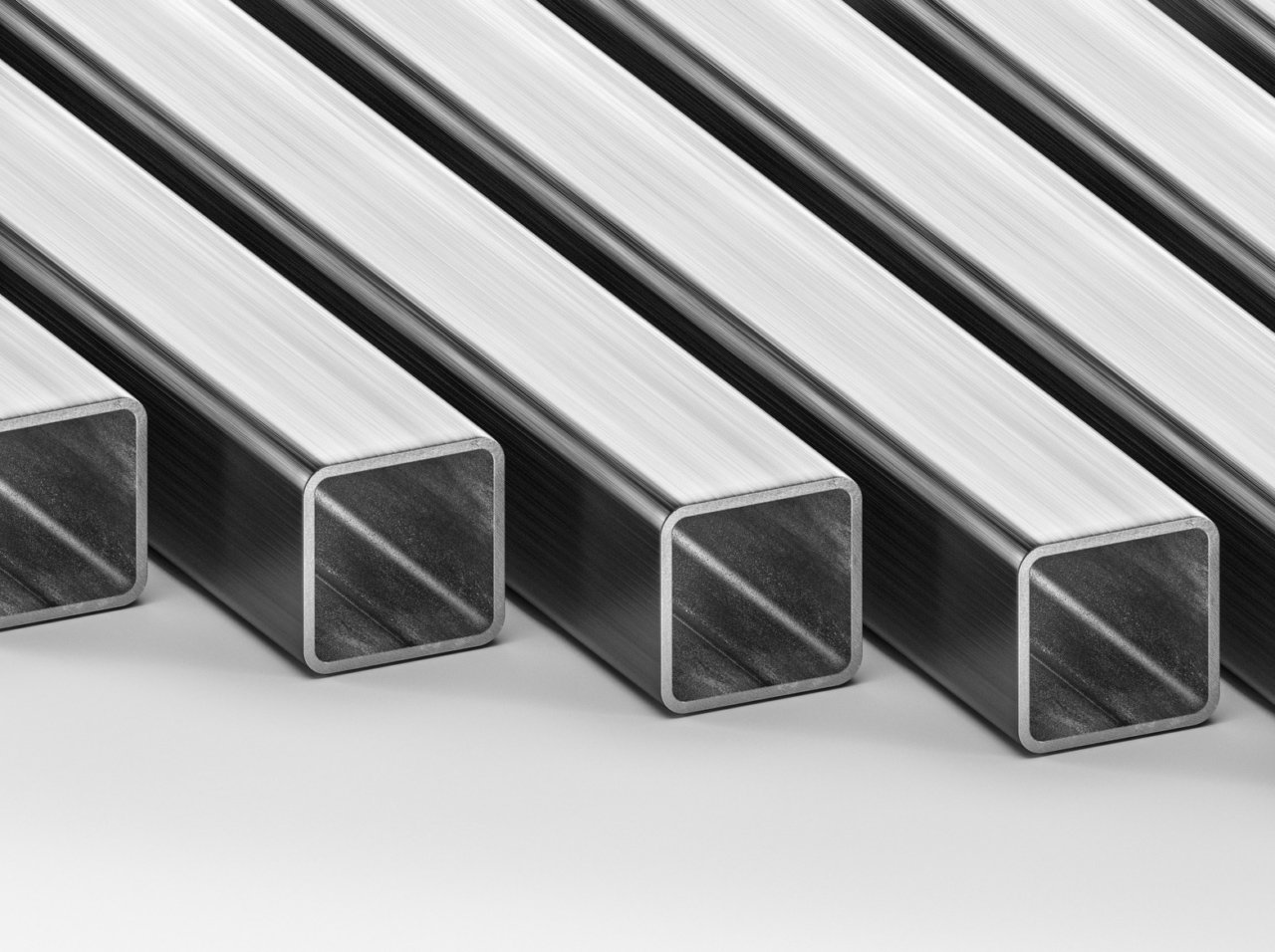

Stainless steel hollow sections for your bus and coach body frames

Our products enhanced with strength enable the manufacturing of even lighter bus bodies with excellent yield strength, elongations, and energy absorption properties.

The high-strength stainless steel hollow sections offer not only lighter structures but also better corrosion resistance and lower life-cycle costs. Tailored products reduce material waste and keep the cost level stable. Compared to a traditional carbon steel bus, life-cycle costs remain low. Additional benefits come from reduced CO2 emissions, fuel costs, and improved passenger capacity.

Stronger stainless, lighter structures

Stalatube’s high-strength stainless steel products offer higher strength with lighter structures and exceptional elongation properties as well as corrosion and fire resistance. Due to high-strength stainless steel’s mechanical properties, you can have much thinner tube wall thickness without compromising the structure’s functionality, stability, or safety. The high-strength stainless steel hollow section will maintain the same outer dimensions and bending resistance as standard materials.

Stalatube’s high-strength classes offer sustainable choices for every purpose. Weight saving equals less material. Material savings, in turn, are equal to cost savings in the initial investment phase. In addition, less material decreases the environmental impact and leads to a smaller carbon footprint. Lighter structural weight also decreases the carbon footprint of the cargo.

High-strength stainless steel has a higher yield and tensile strength and better energy absorption properties than traditional stainless steel grades or structural steel. While offering undeniable strength in applications, high-strength stainless steel can also be combined with other steel grades.

Stainless steel advantages for the transport industry

-

Higher strength, lighter structures – up to 1000 kg off the weight of the bus body

-

Maintenance-free, low life-cycle costs

-

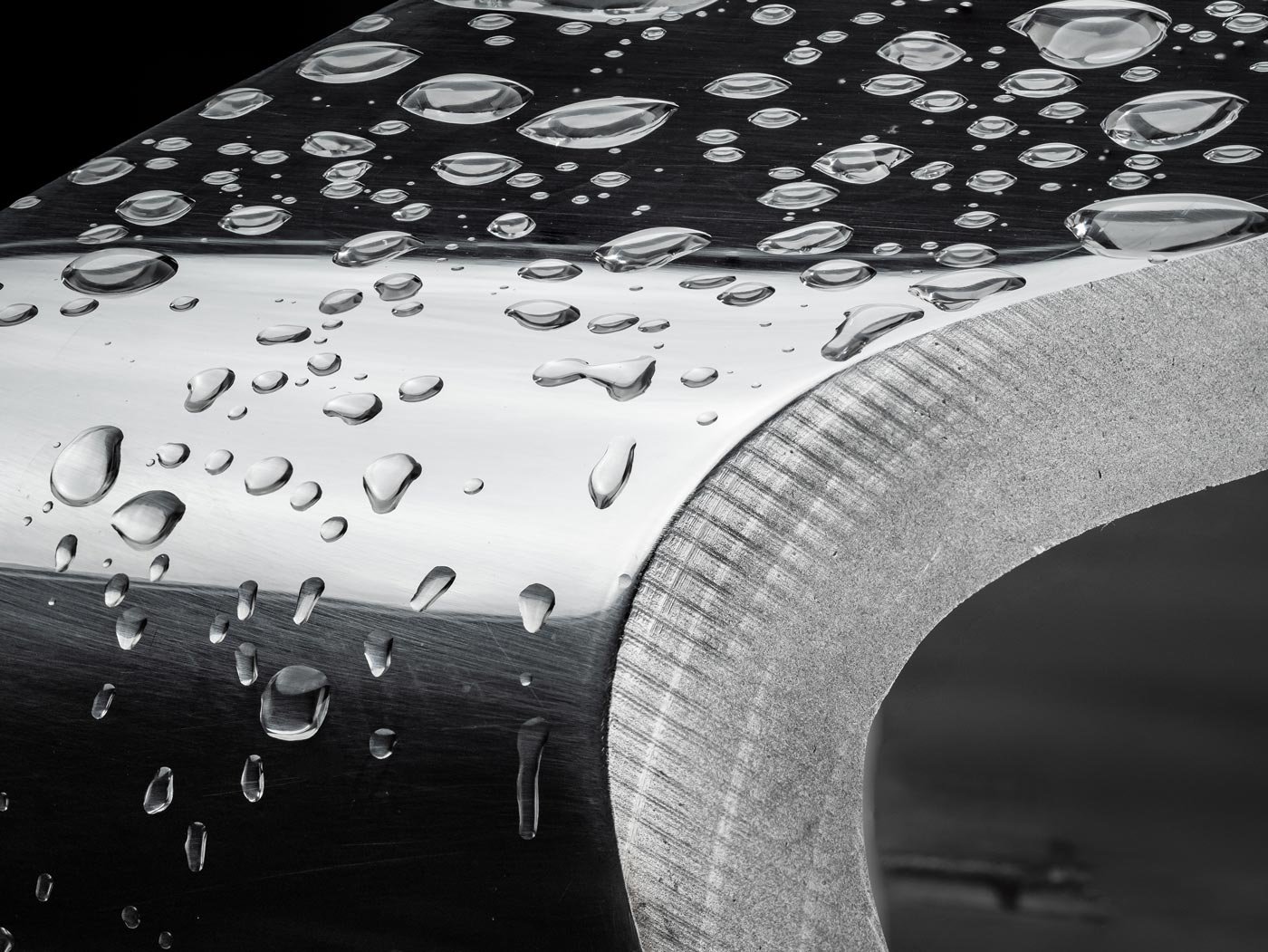

Superior corrosion resistance

-

Tailored products reduce material waste

-

100 % recyclable, low environmental impact

-

Price stability over time due to low nickel content

-

Ready-to-assemble component kits

-

Flexible stocking and delivery options

-

Technical consultation service

Brochure

Stainless steel lightweight solutions for transportation industry

Jori Määttänen

Sales Director

Hollow sections & profiles, Transport Industry

Stalatube Oy (Finland)

+358 50 518 332

jori.maattanen@stalatube.com

AUSTENITIC STAINLESS STEEL

Austenitic stainless steel is the most commonly used stainless steel grade due to its many benefits. Austenitic steel provides excellent formability and weldability. It offers toughness at low temperatures and sustains its mechanical values even when the temperatures rise high. Austenitic steel grades give a 30-minute fire resistance without any additional fire protection.

Also available in STALA high-strength class STALA800.

DUPLEX AND LEAN DUPLEX

Duplex and Lean Duplex answer to the most demanding needs by offering a superior combination of high strength, corrosion resistance as well as lowered life cycle costs. When weight matters or the environment poses a challenge, light, extremely durable, and maintenance-free Duplex and Lean Duplex structural hollow sections are the ideal solution.

Also available in STALA high-strength class STALA630D.

FERRITIC STAINLESS STEEL

Ferritic stainless steel offers a cost-effective, more corrosion resistant alternative to galvanized steel. An ideal choice for structural uses in the transportation industry. Its benefits come from lower life cycle costs, low maintenance needs and a steady price level due to low nickel content. Ferritic can be combined with other stainless and carbon steel structural parts.

The strength can be further strengthened with our own strength class STALA400F.

High-strength stainless steel products

Our high-strength stainless steel products offer not only higher strength with lighter structures but also exceptional elongation properties as well as corrosion and fire resistance. STALA high-strength classes offer sustainable choice in every purpose. In addition to remarkable sustainability benefits, high-strength stainless steel saves you costs and offers strength and safety that the more traditional material choices won’t get you. We offer stainless steel tubes with high-strength classes in the following Austenitic, Ferritic, and Lean Duplex material grades.

Ultimate strength and elongation

STALA800

Our newest high-strength stainless steel hollow section called STALA800 (EN 1.4678). It has an exceptional combination of high strength and elongation. The material can absorb a huge amount of energy in case of an accident, making it ideal for roll-over structures and collision guards.

STALA800 is an excellent choice for bus body structures made mainly from carbon steel. It can be combined with carbon steel to strengthen the critical parts of the structure. E-coating is recommended for better corrosion resistance.

Mechanical properties

- Min. yield strength 800 MPa (116 ksi)

- Min. tensile strength 1000 MPa (145 ksi)

- Min. elongation 25%

High-strength and corrosion resistance

STALA630D

High-strength Lean Duplex steels EN 1.4062 and EN 1.4162 lead to considerable weight-save and provide superb elongation and corrosion resistance. Fortifying them with our own strength class STALA630D will ramp up their yield strength to 630 MPa along with excellent elongation and energy absorption properties.

Combining Ferritic and Lean Duplex leads to the most lightweight bus or coach body that is both cost-effective and durable. A 1000-kilogram decrease in the weight of the bus body is possible through not only material selection but carefully choosing the ideal tube dimensions and thicknesses. Life cycle costs remain low – and the difference is quite remarkable compared to a traditional carbon steel bus. Additional benefits come from reduced CO2 emissions and fuel costs as well as improved passenger capacity.

Mechanical properties

- Min. yield strength 630 MPa (91 ksi)

- Min. tensile strength 750 MPa (108 ksi)

- Min. elongation 20%

Cost-efficient

STALA400F

Ferritic STALA400F is a cost-effective and price-stable material. STALA400F is also a sustainable choice due to its significantly lower CO2 footprint compared to galvanized carbon steel.

Ferritic STALA400F square and rectangular hollow sections, components and sheets are a cost-efficient solution providing good structural corrosion resistance and relatively high strength. Ferritic steel offers the benefits of more highly alloyed stainless steels such as strength, corrosion and abrasion resistance, durability and low maintenance. It is weldable and formable allowing it to be fabricated using conventional technique.

Mechanical properties

- Min. yield strength 400 MPa (58 ksi)

- Min. tensile strength 450 MPa (65 ksi)

- Min. elongation 10%

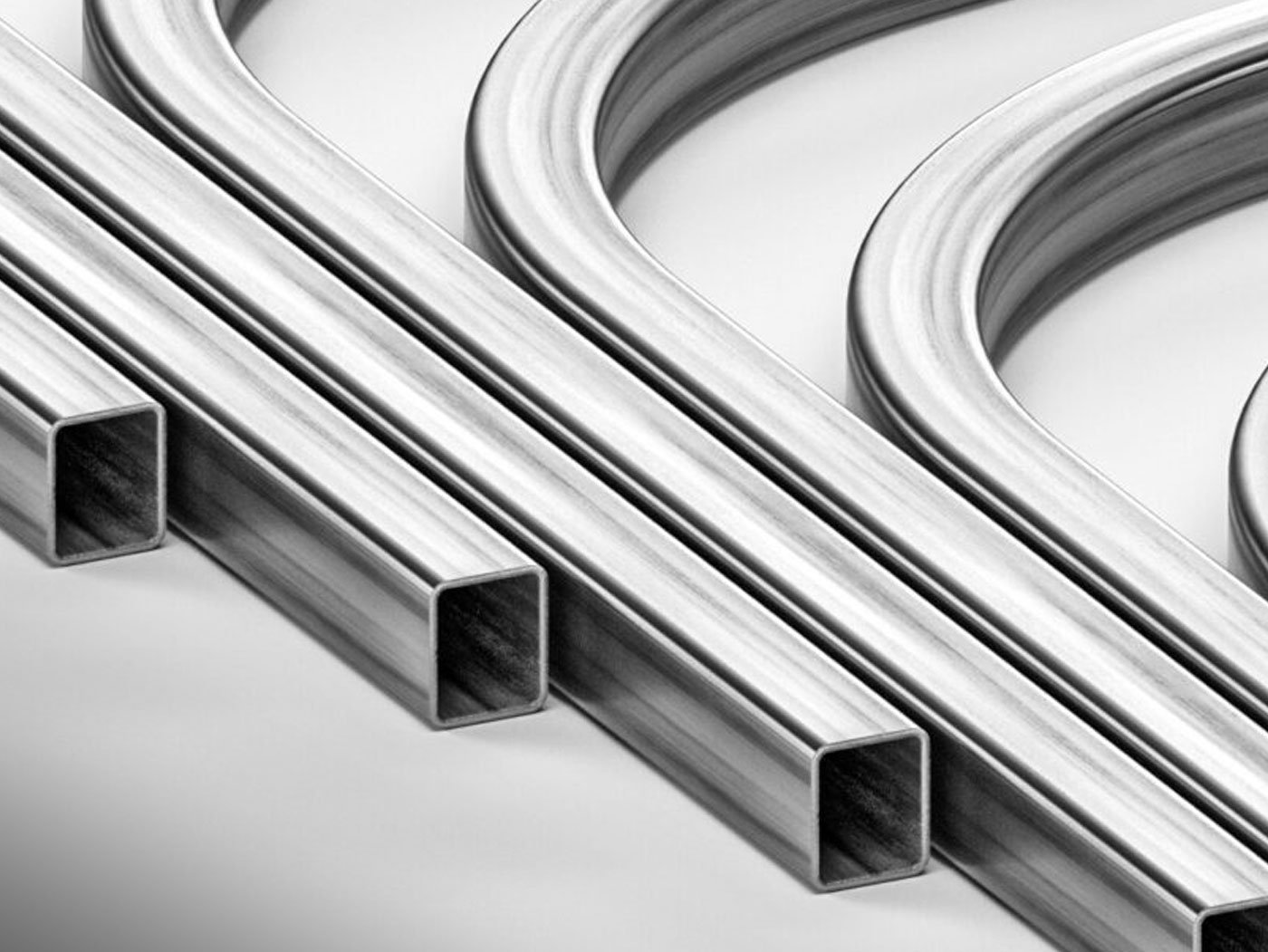

The STALAopti tube offers an excellent combination of flexural strength and light in weight. Increased wall thickness at the end of the tubes allows using higher heat input during welding without the risk of burning through. Reinforcement inside the tube increases buckling resistance significantly.

The optimal solution in those bus body structure areas where stiffness is required. STALAopti offers excellent flexural strength for our customers looking for strength and durability without weight increase and stronger joints. This is a unique solution for strengthening the needed area and eliminating the weight increase at the same time suitable mainly for bus body structures.

Benefits

- High flexural strength and buckling resistance

- Avoid problems related to welding of thin wall thicknesses

- Big weight-saving potential

STALA Opti is available in all stainless steel grades in Stalatube’s product portfolio.

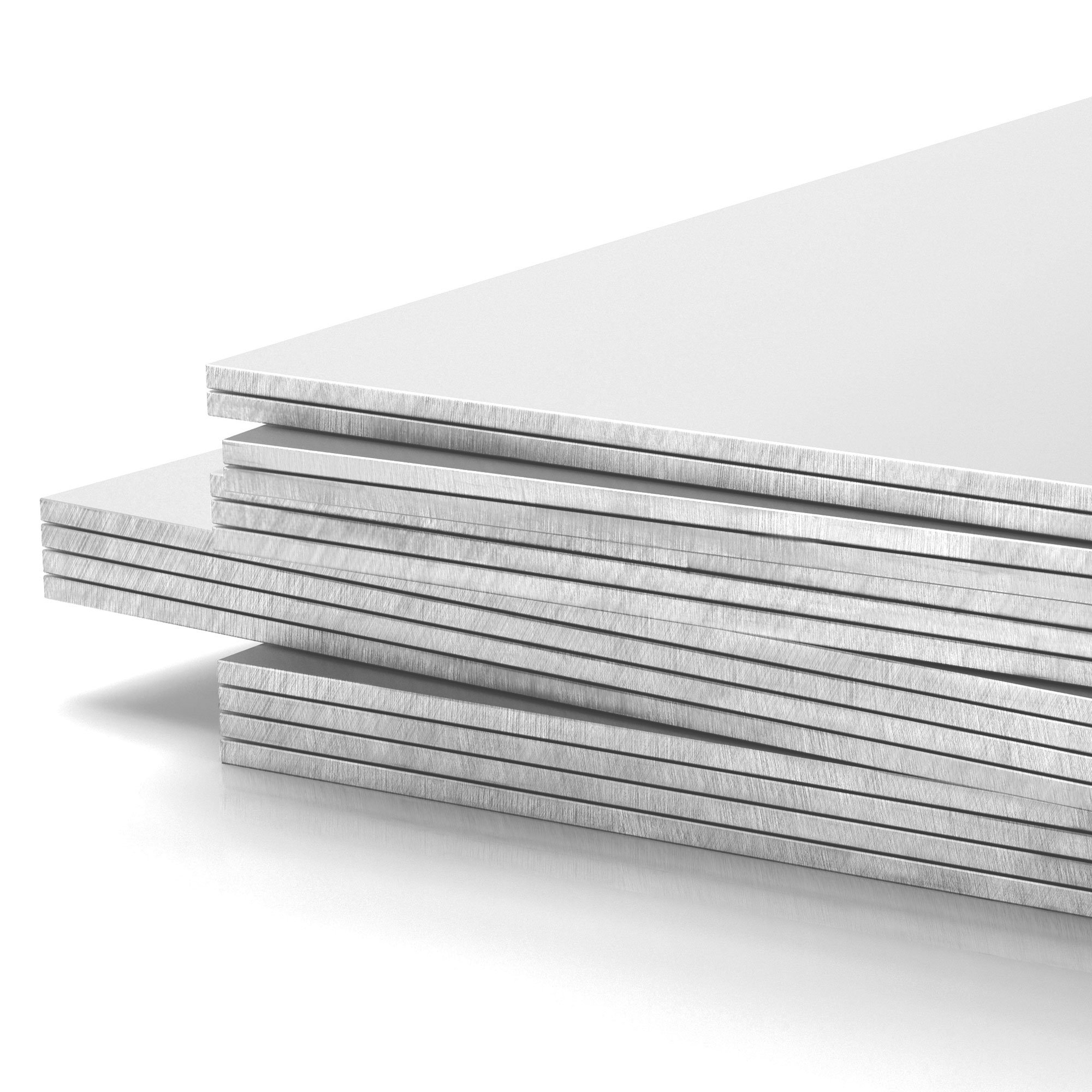

SHEETS

We offer ferritic and duplex sheets in addition to our tube and components offerings. Ferritic sheets are offered in sizes 1250 x 2500 mm up to 10.0 mm thickness. Duplex sheets are offered in sizes 1500 x 3000 mm up to 6.0 mm thickness. Special dimensions by request. The sheets are packed in wooden pallets.

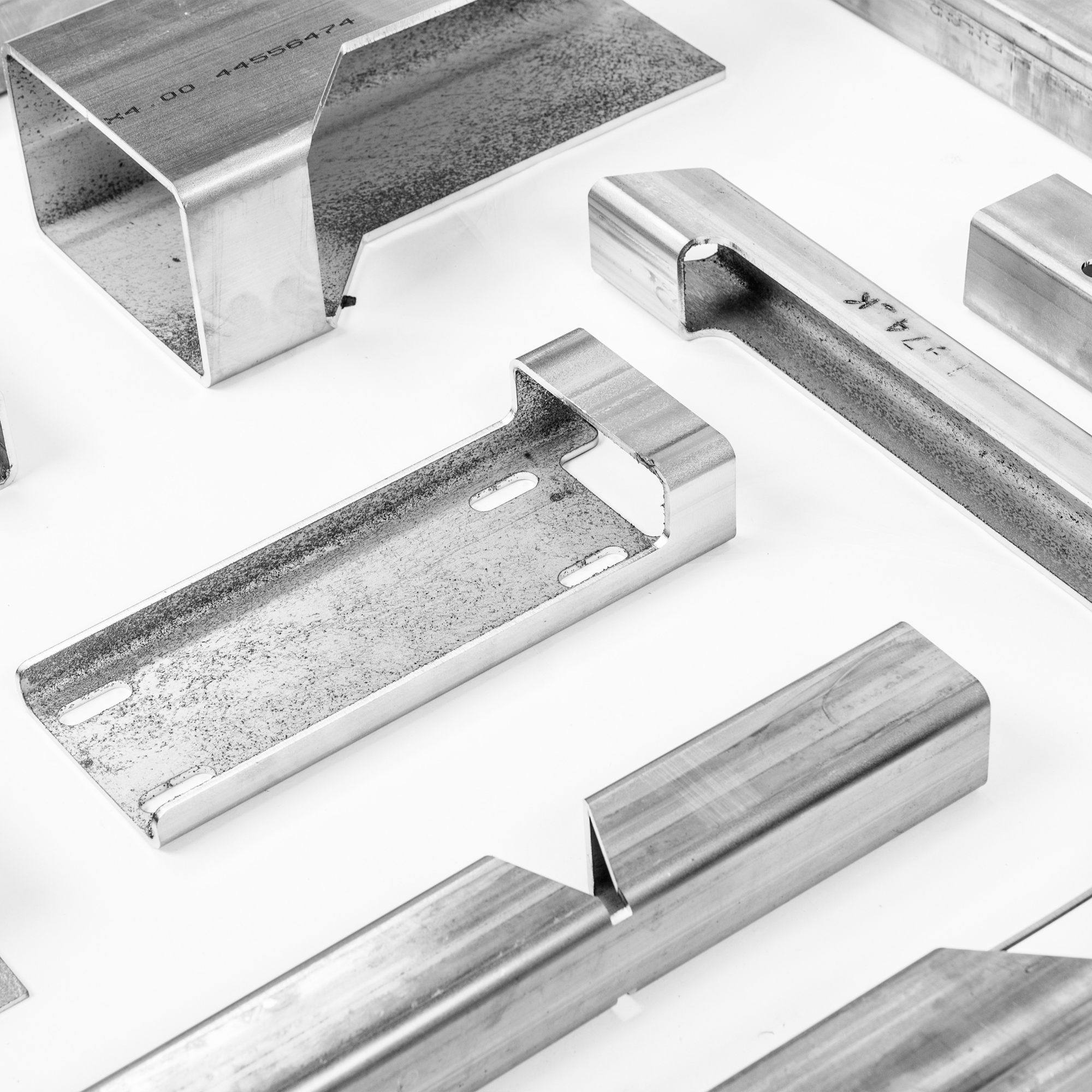

COMPONENTS

Laser cutting, bending, and creating ready-to-assemble component kits are at the core of our services for the transportation industry. Different grades and thicknesses of stainless steel can affect the bending process. Our experts have the best possible understanding of the material properties to help in selecting the appropriate laser and bending method and tools.

ADDITIONAL SERVICES

When your project requires cut-to-length service, special packaging, ready-to-assemble kit packages, timed deliveries or material warehousing at our facility, our value-added smart logistics service comes into play. Let us know your needs and we will deliver.

TECHNICAL CONSULTATION

Our team has a lot of technical experience and know-how in bus body design. Major savings in the total weight of a vehicle can be achieved by optimizing the bus body structure. We are here to help our customers choose the right material and products to maximize the benefits of choosing stainless steel.

Stalatube Oy (Finland)

+358 50 518 332

jori.maattanen@stalatube.com